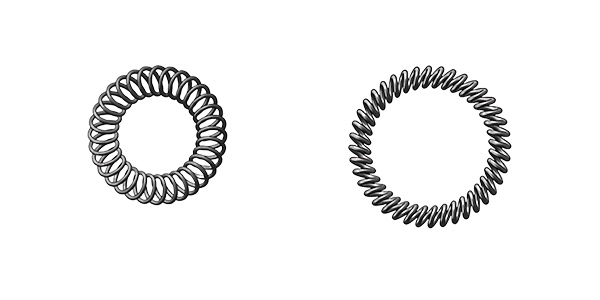

The canted coil spring is a spring whose spiral axis is at a specific angle to the load direction, and realizes compound load support (axial compression + radial torsion) through multi-directional elastic deformation. Its spiral stacking structure can disperse stress and is specially used in scenarios that require multi-dimensional buffering and resistance to eccentric load impact.

Technical Parameters

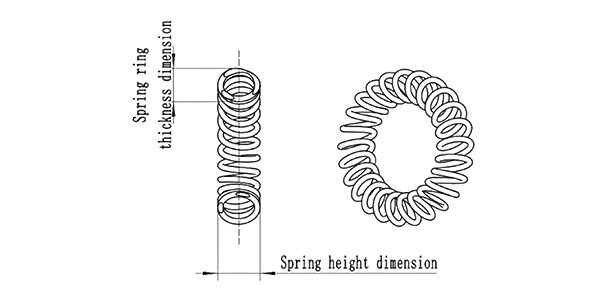

- Wire diameter d (mm): spring wire diameter

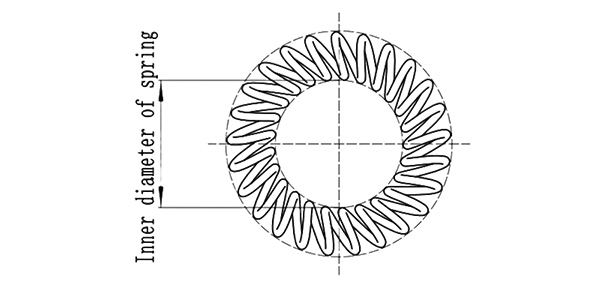

- Inner diameter Di (mm): inner diameter of annular spring

- Outer diameter D (mm): outer diameter of annular spring

- Large diameter of bevel coil W (mm): major axis of bevel coil ellipse

- Small diameter of bevel coil H (mm): minor axis of bevel coil ellipse

- Number of turns Na (turns): total number of turns of bevel coil

- Other requirements: spring purpose, current requirements, welding requirements and other technical requirements, etc.

Features

- Simple structure, small size, less material, low cost; meet the space requirements of device design

- Small size requirements, suitable for compact design; minimum number of components, simplifying the design of connecting devices.

- Multiple point contact and high concentration force can achieve almost lossless contact. Guaranteed large current carrying capacity; good electrical conductivity, high electrical and thermal stability.

- The contact pressure of each contact point is not high, and its silver plating has good wear resistance during opening and closing operations.

- The unique structure gives it a wide working range; allows larger tolerances on the joint surface; has greater adaptability to processing errors and assembly errors, and is more suitable for large-scale production.

Tips for Customizing Canted Coil Springs

- Wire diameter range: φ0.15mm~φ0.3mm

- Technical standards: Conventional products refer to national standards and industry standards; customized products are subject to the final technical standards and technical drawings confirmed by the customer

- Material: Carbon steel (SWC), Alloy steel, stainless steel, music wire/piano, wire (SWP), beryllium copper, etc

- Surface treatment: Zinc, Chorme, Nickel, Silver, Gold, Tin, Powder coating, Oxide black or customized.

Applications

Industrial/automotive/electrical/mechanical equipment, etc., providing current transmission, shielding, locking and other functions.