Compression springs are spiral mechanical parts that store energy through axial compression deformation. They are widely used in scenarios such as buffering, shock absorption, energy storage and resetting. They work by shortening their length when subjected to force and returning to their original shape after unloading.

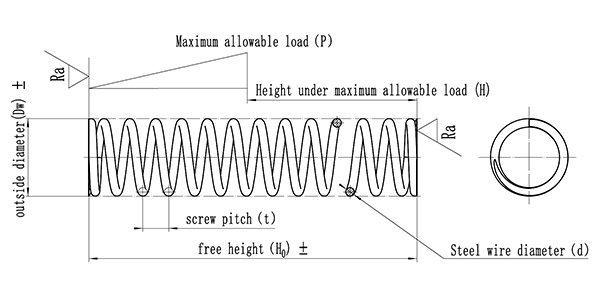

Technical Parameters

- Wire diameter d (mm): spring wire diameter

- Outer diameter D (mm): spring outer diameter

- Length L0 (mm): total length of the spring

- Number of turns Na (turns): total number of turns of the spring

- Direction of rotation: left/right

- Strength requirements: elastic performance, other technical requirements, etc.

Features

- High load-bearing capacity: Can withstand large loads per unit volume.

- Self-resetability: Restores to original shape after unloading, suitable for repeated use scenarios.

- Compact structure: Small size, easy to integrate into complex systems.

- Long life: Alloy steel and other materials have strong fatigue resistance and a cycle life of millions of times.

- Customized design: Can adapt to different needs by adjusting parameters such as wire diameter, number of turns, helix angle, etc.

Tips for Customizing Compression Springs

- Wire diameter range: φ0.08mm~φ8.0mm

- Technical standards: Conventional products refer to national standards and industry standards; customized products are subject to the final technical standards and technical drawings confirmed by the customer

- Material: Carbon steel (SWC), Alloy steel, (SEA9260/ 9254/ 6150/ SUP9/ SUP10/ SUP12 /51CrV4), stainless steel, music wire/piano, wire (SWP), etc.

- Surface treatment: Ep.Zn8.c2C, Ep.Cd5.c2C, Ap.Ni5, Ep.Cr5hd, Ct.p, Ep.Sn5, Ct.o, Custom

Applications

Industry/automobile/motorcycle/electronics/toys/sports/mechanical equipment, etc., providing buffering and shock absorption functions.