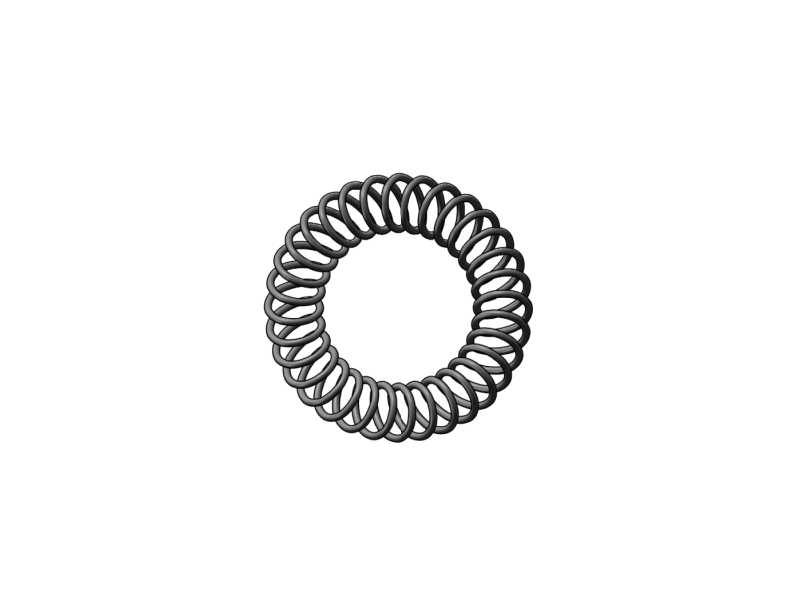

A tension spring is a helical spring that stores energy by axial stretching and deformation. It usually has hooks or threaded structures at both ends to transmit tension. It deforms when stretched by external forces during operation and returns to its original length after unloading. It is widely used in scenarios such as pre-tightening, tension adjustment, and reset control.

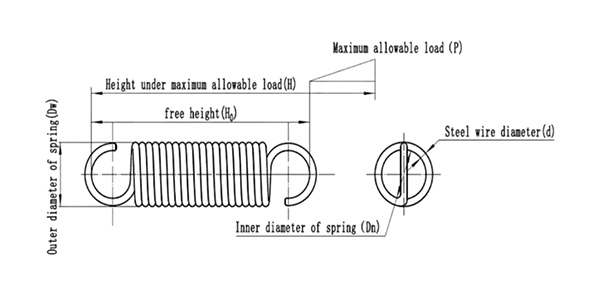

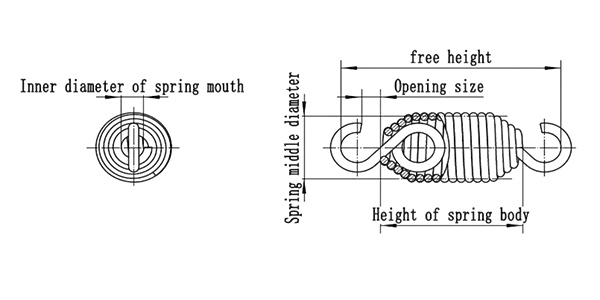

Technical Parameters

- Wire diameter d (mm): spring wire diameter

- Outer diameter D (mm): spring outer diameter

- Length including hook L0 (mm): total length of spring

- Number of turns Na (turns): total number of turns of spring

- Direction of rotation: left/right

- Hook form: round hook/semi-circular hook/U hook/variable hook, etc.

- Strength requirements: elastic performance, other technical requirements, etc.

Features

- Preload design: Quick response through initial tension to avoid system loosening.

- High-precision load: Linear deformation characteristics, precise control of tension range.

- Fatigue resistance: Alloy steel material can withstand more than 10⁶ stretching cycles.

- Compact installation: Hook-and-loop structure adapts to narrow spaces.

Tips for Customizing Extension Springs

- Wire diameter range: φ0.08mm~φ4.0mm

- Technical standards: Conventional products refer to national standards and industry standards; customized products are subject to the final technical standards and technical drawings confirmed by the customer

- Material: Carbon steel (SWC), Alloy steel, (SEA9260/ 9254/ 6150/ SUP9/ SUP10/ SUP12 /51CrV4), stainless steel, music wire/piano, wire (SWP), etc.

- Surface treatment: Ep.Zn8.c2C, Ep.Cd5.c2C, Ap.Ni5, Ep.Cr5hd, Ct.p, Ep.Sn5, Ct.o, Custom

Applications

Industrial/automobile/motorcycle/electronics/toys/sports/mechanical equipment, etc., providing reset function.