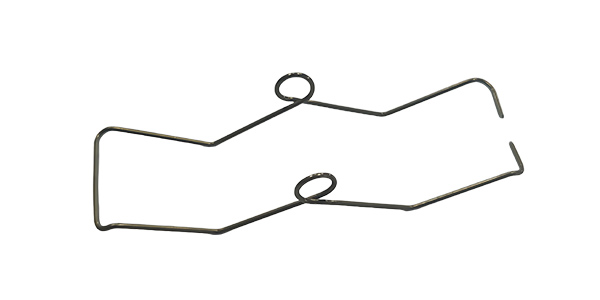

The difference between special-shaped springs and regular springs is that the springs themselves are irregular, with bends and a large number of complex angle designs, and the manufacturing and processing skills are relatively demanding, and there are also requirements for equipment. Special-shaped spring products can be mass-produced using computer-controlled automated machines. Due to the many winding angles and bends, the production speed is slow. Due to its complexity, manual molds can also be used for small-batch processing.

Technical Parameters

Tips for Customizing Special-shaped Springs

- Wire diameter range: φ0.08mm~φ4.0mm/δ0.2mm~δ5.0mm

- Technical standards: Conventional products refer to national standards and industry standards; customized products are subject to the final technical standards and technical drawings confirmed by the customer

- Material: Carbon steel (SWC), Alloy steel, SEA9260/ 9254/ 6150/ SUP9/ SUP10/ SUP12 /, 51CrV4, stainless steel, music wire/piano, wire (SWP), beryllium copper, etc.

- Surface treatment: Ep.Zn8.c2C, Ep.Cd5.c2C, Ap.Ni5, Ep.Cr5hd, Ct.p, Ep.Sn5, Ct.o, Custom

Applications

Industry/Automobile/Motorcycle/Electronics/Toys/Sports/Mechanical Equipment, etc.